Like the muffler in a car exhaust, the Noise Mitigation System targets specific low frequencies that produce the most noise. This method distinguishes the Noise Mitigation System from other systems.

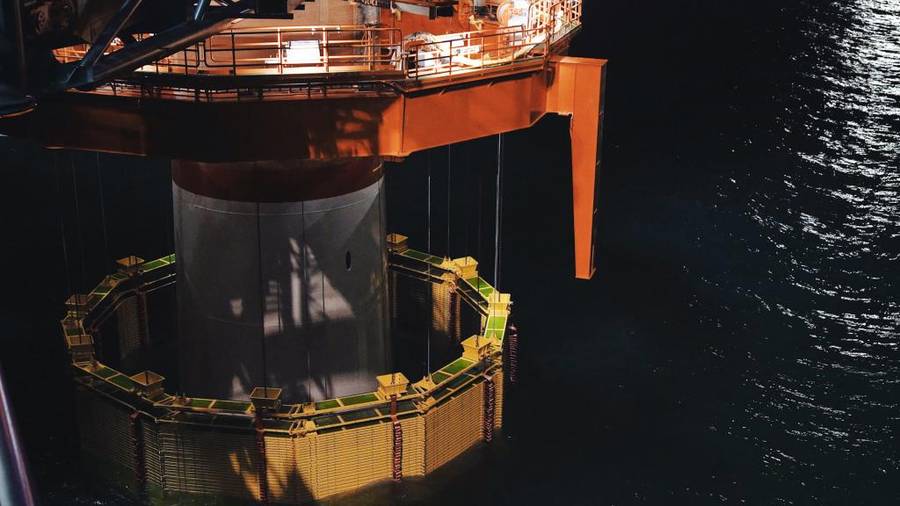

Targeting the specific frequencies is achieved by special acoustic resonators. These resonators that look like inverted coffee cups are built into horizontal frames, which are unfolded around the pile to be driven into the seabed. By putting the Noise Mitigation System into the water, the cups are filled with air. The air pockets are dimensioned to absorb the sound frequencies that produce the most noise during offshore pile driving. This attenuates the most damaging noise to mammals.

Another added value of the Noise Mitigation System is the fact that waves and currents have virtually no impact on the system. This is due to its open but robust design. The blinds simply go up and down.

Testing

The Noise Mitigation System was extensively tested in 2018. The results showed that the Noise Mitigation System targets the low frequencies. Combined with the Big Bubble Curtain, a system that reduces the higher peak frequencies, they meet the requirements set by the Dutch government.

The Big Bubble Curtain is best described as a long hose with holes, into which air is pumped during pile driving. The air escapes through the holes and creates a curtain of bubbles. The Big Bubble Curtain not only dampens high frequencies, but the hose also dampens noise coming from the seabed further away from the sanctuary site. The Noise Mitigation System is placed directly around the monopile, while the Big Bubble Curtain is placed on the seabed 100 metres around the pile driving site.

First commercial commissioning

Due to the positive test results, Van Oord began commercial use of the Noise Mitigation System earlier this year. During the installation of wind farms Borssele III and IV, the Noise Mitigation System with a Double Big Bubble Curtain was used. This was necessary because of the season when noise emission standards were higher.

Van Oord used an improved version of the Noise Mitigation System. The company reduced the distance between the resonator levels. They also extended the Noise Mitigation System with 'bubble diffusers' to get as much air into the resonators as possible. This maximised the air in the Noise Mitigation System's water column. These modifications to the Noise Mitigation System enhanced the damping effect at the lower frequencies.

Results of the first commercial use

All in all, the combination of the improved Noise Mitigation System and the addition of a Double Big Bubble Curtain resulted in noise attenuation between 12 and 25 dB. Specifically, the combination produced a minimum of 157 and a maximum of 172 dB during pile driving at Borssele III and IV. Taking into account the piling season, when standards are higher, the system more than met the Dutch standard for underwater noise.

During commissioning of the Noise Mitigation System, the predictability of the resonators proved to be better than expected and the attenuation of frequencies could be accurately predicted. This indicates that the system can be adapted to other conditions, such as deeper water where other resonators may be needed. This makes the Noise Mitigation System a suitable solution for future projects.

Further enhancements

Van Oord plans to continue using the system and improve it even further. The biggest challenge during the operation at the Borssele sites was the handling of the frame. The system had to have enough ballast to reach the seabed, but also not be too heavy that it could not be attached to a vessel.

Noise reduction system; the future standard noise reduction method?

For Van Oord, the aim is for the Noise Mitigation System to become the standard method for noise reduction during offshore pile driving. Through initial commissioning at Borssele III and IV, knowledge has been built up to optimise the system. For instance, improving the robustness of the system will contribute to further silence for a wider frequency spectrum. To easily adapt the system to desired attenuation levels in specific frequency ranges, Van Oord is considering making the system more flexible. In addition, the company is considering the idea of placing more resonators in the water column.